What Is Product Variation?

Product variation refers to managing multiple versions of the same base product using defined attributes rather than creating separate, disconnected items.

Each unique combination of attributes creates a variant, which can be tracked independently for inventory, purchasing, manufacturing, and fulfillment.

Common Product Variation Attributes

- Size

- Color

- Gender

- Material

- Finish

- Configuration

- Length, weight, or capacity

- Packaging or bundle type

Variation allows businesses to offer flexibility to customers while maintaining operational control in ERP systems.

Why Product Variation Is Essential in ERP Inventory Management

Variation exists because real-world inventory decisions happen at the variant level, not the product level.

Without proper variation modeling, businesses experience:

- Stockouts in specific sizes or colors

- Over-purchasing of slow-moving variants

- Inaccurate inventory valuation

- Fulfillment and picking errors

- Weak demand forecasting

ERP inventory management systems rely on variation to ensure accuracy, traceability, and scalability.

Managing Inventory Without Part Numbers Using Variations

Many businesses begin operations without standardized part numbers or SKUs. This is common in:

- Apparel and fashion

- Furniture and home goods

- Custom manufacturing

- Contract production

- Early-stage or fast-growing companies

Parent Item + Variation Model

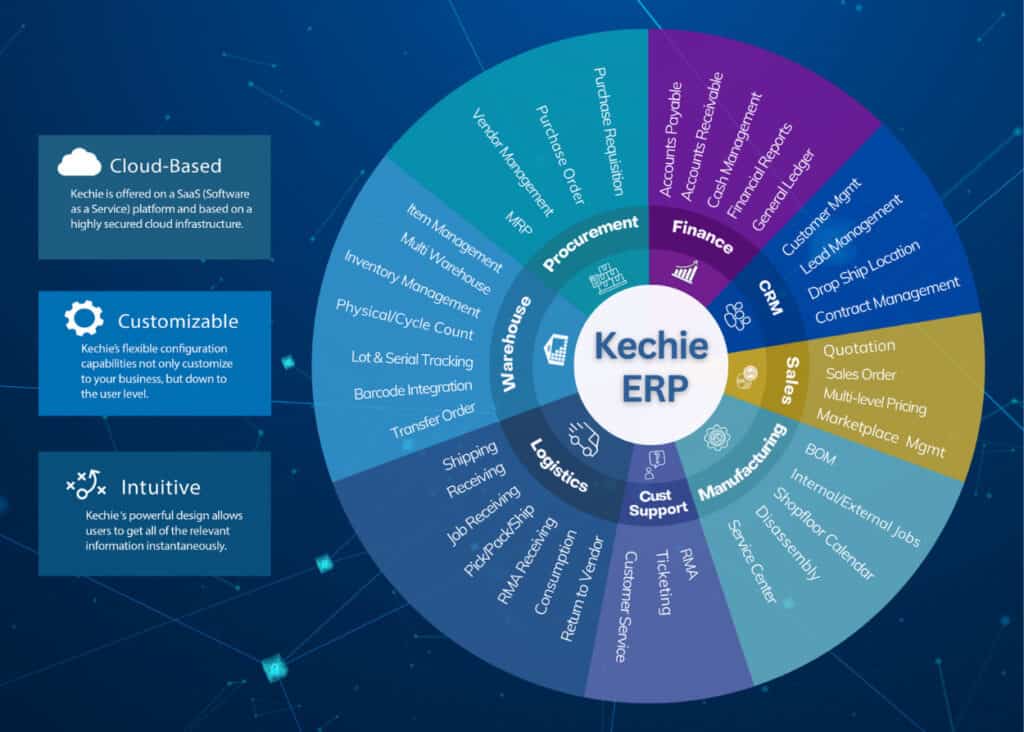

ERP systems like Kechie address this using a parent item with variation attributes.

How This Works in Practice

- A base (parent) item represents the generic product

- Variation attributes define differences (size, color, gender, etc.)

- Inventory is tracked at the variant level

- Formal SKUs or part numbers can be introduced later

This approach allows businesses to operate immediately while maintaining inventory visibility and control.

Managing Inventory With Variations in Kechie ERP

Kechie ERPinventory management software supports variation-based inventory tracking for both stocked and manufactured items.

Key Kechie ERP Capabilities

- Define multiple variation attributes per item

- Track inventory quantities per variant

- Assign costs, pricing, and barcodes at the variation level

- Set reorder points by variant

- Maintain reporting at both parent and variant levels

This ensures inventory decisions are based on actual demand patterns, not averages.

Apparel ERP Example: Size, Color, and Gender Variations

Apparel inventory is one of the clearest examples of why variation is essential.

Base Item: Cotton T-Shirt

Variation Attributes:

- Gender (Men’s, Women’s, Unisex)

- Size (S, M, L, XL)

- Color (Black, White, Blue)

Each gender–size–color combination represents a distinct inventory unit that must be tracked independently.

An apparel ERPsystem like Kechie enables:

- Accurate stock tracking by size and gender

- Better demand forecasting

- Reduced returns and fulfillment errors

- Cleaner eCommerce and POS integration

Manufacturing Items With Variations in ERP Software

In manufacturing ERP systems, variations affect more than inventory—they directly impact production.

Common Manufacturing Variation Drivers

- Dimensions or sizing

- Material substitutions

- Finish or coating options

- Customer-specific configurations

How ERP Software Handles Manufacturing Variations

- Shared Bills of Materials (BOMs) with variant-specific rules

- Accurate costing per variation

- Variant-level production planning

- Material requirement planning by configuration

This is critical for furniture manufacturing, apparel production, and configurable goods.

Variation vs Separate Items in ERP Systems

A common ERP design question is whether to use variations or separate items.

Use Variations When:

- The base product is fundamentally the same

- Differences are attribute-driven

- Operational workflows overlap

Use Separate Items When:

- Function or use case differs

- Cost structure changes significantly

- Manufacturing processes diverge

ERP platforms like Kechie support both approaches, allowing businesses to model inventory realistically.

Business Benefits of Variation-Based ERP Inventory Management

Using product variations in ERP software delivers measurable benefits:

- Higher inventory accuracy

- Lower carrying costs

- Improved purchasing and production planning

- Stronger demand forecasting

- Better integration with accounting and eCommerce platforms

Variation ensures ERP systems reflect how products are actually bought, stored, and produced.

Key Takeaway

Product variation is the foundation of effective ERP inventory and manufacturing management.

Whether inventory begins without part numbers or already includes them, variation provides the structure needed for accuracy, scalability, and operational clarity. ERP software like Kechie ERP is built to manage this complexity, making variation a core component of modern inventory systems.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

In This Article

-Common Product Variation Attributes

-Why Product Variation Is Essential in ERP Inventory Management

-Managing Inventory Without Part Numbers Using Variations

-Managing Inventory With Variations in Kechie ERP

-Manufacturing Items With Variations in ERP Software

-How ERP Software Handles Manufacturing Variations

-Variation vs Separate Items in ERP Systems

-Business Benefits of Variation-Based ERP Inventory Management

Key Takeaway