Supply Chain Resilience in 2025: Nearshoring Trends & the Bullwhip Effect

The past few years have been a wake-up call for global supply chains. From pandemic disruptions to geopolitical tensions and extreme weather events, companies have realized that resilience is no longer optional — it’s essential. Two of the most important strategies in this conversation are nearshoring and managing the bullwhip effect.

In this article, we’ll explain what these terms mean, why they matter, and how modern ERP and supply chain software like Kechie ERP can help companies adapt and thrive.

Nearshoring Trends: Bringing Production Closer to Home

For decades, companies prioritized low-cost, offshore manufacturing hubs — particularly in Asia. While this strategy helped cut expenses, it also created long, fragile supply chains vulnerable to disruption.

Now, businesses are turning to nearshoring: shifting production and sourcing closer to their main markets. For example, U.S. firms are increasingly working with suppliers in Mexico and Latin America, while European companies are exploring Eastern Europe and North Africa.

Why Nearshoring is Gaining Momentum

1. Risk Reduction: Shorter supply chains mean fewer disruptions from shipping delays, port congestion, or global conflicts.

2. Faster Response Times: Being closer to customers allows for quicker replenishment and more agile demand planning.

3. Balanced Costs: While labor may be higher than in offshore regions, savings in transportation, tariffs, and lost sales often offset the difference.

4. Sustainability: Nearshoring reduces carbon footprints by cutting down on long-haul shipping routes.

Example in Action

Several U.S. automakers have shifted parts production to Mexico. The shorter distance allows for just-in-time manufacturing and reduces the risk of supply shortages caused by overseas shipping delays.

The Bullwhip Effect: A Hidden Supply Chain Challenge

While nearshoring helps reduce physical risks, companies must also deal with information distortions in their supply chains. That’s where the bullwhip effect comes in.

The bullwhip effect happens when small changes in customer demand trigger increasingly larger fluctuations as they move up the supply chain. A slight sales spike at retail level can lead distributors, manufacturers, and suppliers to overreact — creating excess inventory, inflated costs, and inefficiency.

Common Causes of the Bullwhip Effect

- Inaccurate Forecasting: Over-reliance on short-term sales spikes.

- Order Batching: Placing large, infrequent orders instead of smaller, steady ones.

- Price Distortions: Discounts or promotions that cause artificial demand.

- Lack of Transparency: Poor communication between retailers, distributors, and suppliers.

Ways to Minimize the Bullwhip Effect

1. Data Sharing: Improve visibility with connected ERP systems.

2. Smarter Forecasting: Use AI and analytics to improve demand predictions.

3. Frequent Orders: Smaller, more regular orders help smooth demand.

4. Collaborative Planning: Models like CPFR (Collaborative Planning, Forecasting, and Replenishment) keep partners aligned.

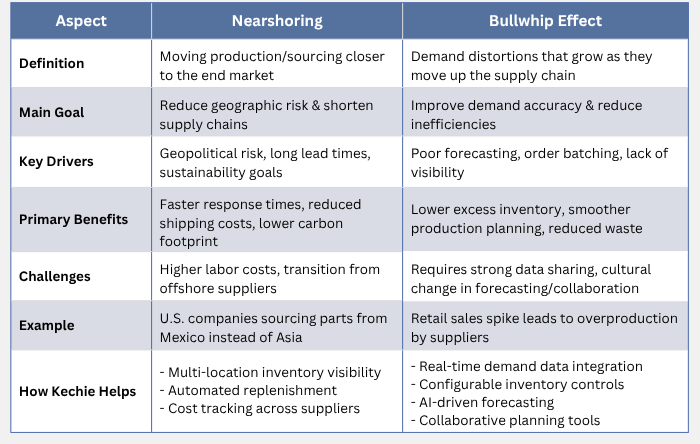

Nearshoring vs. Bullwhip Effect: A Side-by-Side Comparison

How ERP & Supply Chain Software Like Kechie Helps

Resilience isn’t just about strategy — it’s about execution. This is where modern ERP, inventory management, and supply chain software come in. A platform like Kechie ERP gives businesses real-time visibility, automation, and control to put these strategies into action.

Supporting Nearshoring Strategies

- Multi-Location Visibility: Track inventory across nearshored warehouses or facilities in real time.

- Faster Replenishment: Automate order workflows to keep products moving smoothly between regional suppliers and customers.

- Cost Tracking: Monitor landed costs, tariffs, and supplier performance to confirm the ROI of nearshoring.

Reducing the Bullwhip Effect

- Real-Time Demand Data: Kechie connects sales, inventory, and purchasing in one system so all partners see the same demand signals.

- Configurable Controls: Set rules for cycle counts, replenishment, and safety stock by ABC code, location, item, or category.

- Advanced Forecasting: AI-driven analytics improve demand planning accuracy.

- Collaboration Tools: Enable suppliers, distributors, and manufacturers to share information seamlessly.

With Kechie, companies can layer nearshoring strategies with bullwhip reduction tactics, creating supply chains that are not only shorter but also smarter.

Final Thoughts

In 2025 and beyond, businesses can’t afford fragile supply chains. Nearshoring reduces risks from global distance, while tackling the bullwhip effect minimizes costly inefficiencies.

The companies that thrive will be those that pair these strategies with technology. With Kechie ERP, organizations gain the tools to:

- Build resilient supply chains through real-time visibility

- Reduce bullwhip distortions with accurate forecasting

- Adapt faster with flexible, configurable inventory management

The result? Supply chains that are faster, stronger, and more resilient.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!